Review and Outlook on Municipal Solid Waste Smart Incineration

YING Yuxuan, LIN Xiaoqing, WU Angjian, LI Xiaodong

Abstract: Based on the advantages and disadvantages of technologies that applied in incineration disposal, including internet of things, incineration status diagnosis, online real-time monitoring of pollutants, as well as artificial intelligence algorithms, this paper reviews the domestic and foreign research status on intelligent monitoring, automatic control, and management of processes composed by municipal waste collection, transportation and storage, incineration disposal, and pollutant emission control. Furthermore, the future development of intelligent incineration technology has been prospected, and we suggest to carry out systematic integration and coupling of the existing subsystems and modules, build transient closed-loop feedback and optimization model through big data analysis and cloud computing platform, further develop intelligent incineration technologies and equipment.

Keywords: Renewable resource; Municipal waste; Waste disposal; Intelligent management; Automatic control; Smart incineration; Pollution

A digital management system for municipal waste collection and storage is mainly used to effectively acquire municipal waste sources, types, basic physical and chemical properties, stacking characteristics as well as waste output and final disposal links, work out the optimal collection and transportation path by artificial intelligence algorithm and analyse waste components and operation parameters from other incineration plants, so as to effectively predict the waste calorific value and carbon emission; it is indispensable to establish an integrated waste storage, transportation and incineration system and online adjust the storage capacity in a waste pool according to the incineration operating parameters in order to improve the combustion conditions inside a furnace and provide references for the automatic combustion system.

Fig.1 Structure chart of municipal waste collection and transport smart management system

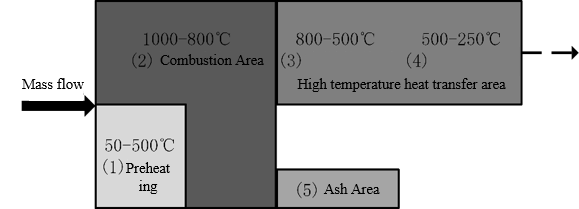

An automatic incineration process control system mainly involves research on the intelligent detection and diagnosis of flame images and signals during the incineration, so as to effectively master incineration characteristics and realize incineration optimization; combustion chamber monitoring technology mainly consisting of thermoelectric couple, infrared temperature measurement and acoustic temperature measurement, of which the acoustic temperature measurement system is used and coupled with a combustion chamber image recognition system to realize the “point- line - surface - body” temperature field reconstruction and improve the furnace inside temperature measurement accuracy and equipment lifetime; online monitoring on operating parameters during the incineration, such as boiler load, combustion chamber pressure, smoke oxygen content, incendiary material layer thickness, gate temperature, burnout temperature and main steam temperature, which can be controlled and regulated by T-S fuzzy control algorithm, HSIC algorithm and PLC control technology and so on, so as to enhance the robustness and accuracy of the control system, avoid any overshoot or oscillation, improve the control quality and ensure the stable combustion; intelligent management on pollutants during the incineration, such as waste water and ash, including realization of incineration optimization based on multiple technical paths, to reduce the generation of unburned bottom ash. In the future, the Internet of Things (IOT) technology can be used for a full-process intelligent management on secondary potential pollution sources such as ash and for utilizing it as resources such as building material and thermal treatment.

During the incineration, municipal wastes tend to produce ash, which will have an adverse effect on the ecological environment and human health if disposed improperly. The ash is mainly composed of non-combustible inorganic substances and some unburned combustible organic substances, specifically including bottom ash (BA) and air pollution control residues (APCR). Bottom ash involves bottom slags at the furnace hearth such as molten slag, glass, ceramics and metal. The type and nature of these slags depend largely on the nature of waste in the furnace, the control over combustion temperature and the property of the flue gas pollution control device, accounting for about 80%~90% of the total mass of ash and representing a larger resource potential [59]. Air pollution control residues (APCR) include captured objects by flue gas purification system and heat recycling system, such as smoke ash, injected absorbent and flue gas condensation product as well as bottom ash at the bottom of the chimney, and it absorbs most harmful substances in flue smoke. According to the Household Garbage Incineration Pollution Control Standards (GB18485-2014), saying “air pollution control residues (APCR) incinerated from municipal waste should be managed as hazardous waste [60]”, the air pollution control residues (APCR) should not be delivered to the landfill before residue leaching toxicity analysis and qualified stabilization treatment. Therefore, it is necessary to carry out intelligent control over the incinerated bottom ash and air pollution control residues, including the intelligent optimization management process of combustion optimization control and final ash disposal during the incineration. As stated above, the combustion optimization control mainly focuses on the reconstruction of the temperature field and the real-time monitoring on the incineration status and the feedback control over the automatic combustion system by multiple technical means such as thermoelectric couple, acoustic temperature measurement, infrared spectroscopy, etc. A big data-driven model and a pollutant coupling operation parameter correlation prediction model are used for advance regulation to ensure the full and stable combustion of waste in the furnace and reduce the generation of unburned furnace ash.

For the existing incineration products, such as ash and other potential secondary pollution sources, a full-process intelligent management is necessary for collection, transportation, disposal and utilization, etc. Allegrini et al [61] from Technical University of Denmark made a life cycle assessment (LCA) on the full-scale municipal waste incineration bottom ash management and recycling system composed of slag sorting system, conveying system, batching system, mixing system, distributing system, modeling system, demodeling system, hydraulic system and electrical control system, revealing that the bottom ash management system has less environmental hazards than air pollution control residues (APCR) during the collection, transportation and disposal or recycling, realizing unhumaned or automatic control with respect to the management and achieving a break-even point. In terms of disposal, pH of bottom ash has stronger buffering capacity, it can enter the landfill after technological processing, or it is used to pour roadbeds, produce concrete and baking-free bricks, etc[62-64]. Sun et al [65] from Tsinghua University summarized APCR incineration management on municipal waste and relevant laws and regulations in the United States, as well as corresponding disposal methods such as separation method, stable solidification and thermal treatment of residues, etc.; Wang Xiaodong et al [66] analyzed a typical case of APCR incineration equipment from Shanghai, recommending management on the generation, temporary storage, pretreatment, transportation and other links in addition to basic requirements for environmental compliance, according to relevant regulations for hazardous waste, then packing and transportation of container bags to control flying dust and secondary pollution during transportation; APCR is generally delivered to the landfill after stabilization treatment, also used as building material, fertilizer, soil conditioner and adsorbent after leaching toxicity test and stabilization [67]. At present, there are fewer researches on the intelligent management of ash at home and abroad. In the future, the whole process of ash disposal can be monitored online based on the Internet of Things technology to optimize the transportation paths, make them link an accurate data statement and realize the visualization and digitization.

Fig.2 Incineration and disposal process of wastes in the plant

The pollutant emission intelligent control system performs online monitoring and closed-loop feedback control of pollutants such as dust, acid gas and dioxin, the intelligent control over dust and acid gas is realized by real-time monitoring of flue gas emission data, intelligent control modules such as neural network algorithm and data networking communication are adopted to accurately regulate feeding materials such as lime and activated carbon to reduce any waste and provide early warning by acid gas concentration prediction model. The concentration of dioxin is a key monitoring indicator, its online monitoring technology mainly involves online indirect detection method and soft measurement method for indicators, of which the rapid online dioxin monitoring system based on the indicator correlation detection is currently at the engineering demonstration stage. The online monitoring technology can be complementary to the long-time offline detection. Before and during the combustion, detected data are used for real-time regulation of operation parameters to achieve the target of near-zero emission.

In summary, major waste incineration plants in China mainly adopt such control methods for dioxin, including control over front-end combustion raw materials and feeding links, combustion optimization and emergency disposal control of the combustion process as well as combustion end emission monitoring and feedback control, of which the monitoring on dioxin is also developing from the long-time sampling offline detection to the monitoring technology integrating long-time sampling offline monitoring with online monitoring. How to more accurately describe the generation process of strongly-coupled nonlinear dioxin and establish an online dioxin monitoring system with more instruction significance will present research significance and realistic application significance in the field of waste incineration in China. Especially for the online dioxin monitoring system based on indicator model applied to plants, it is essential to further improve the stability, accuracy and practicality of online equipment and data acquisition is performed to support the establishment and perfection of national standard emission indicators; integrating multiple working procedures such as waste storage and transportation, combustion inside the furnace, steam power generation, flue gas disposal and emission monitoring, our research aims at the collaborative optimization technology reducing the emission concentration of dioxin, which will be a further research direction in the future.

Fig.3 Generation area chart of dioxin during incineration

For the current situations of municipal waste disposal process in China, such as complex ingredients, bad operation stability, low automatic level and so on, we can carry out optimization and expectation from the following aspects:

1) More samples are employed to further exercise the intelligent waste collection, storage and transportation system algorithm model, improve the collection and transportation efficiency and the prediction accuracy and time resolution of calorific values of waste in the warehouse, develop from intelligent equipment to service-based robot in the intelligent waste classification field and intelligentize the collection and transportation of municipal waste.

2) Further researches on automatic recognition and processing and acoustic temperature measurement and other technologies for developing flame images, especially combustion chamber 3D temperature field monitoring technology, can achieve the “point-line-surface-body” temperature measurement technology progress and make it link with waste preheat prediction model and online incineration status diagnosis and prediction system for waste pools to intelligentize the testing equipment of waste incineration plants.

3) Mostly, the automatic control system for incineration process is theologically verified by computer programming simulation rather than practical testing, so a further test is necessary.

4) For an online pollutant emission monitoring system applied to power plants, especially an online dioxin rapid monitoring system based on indicator model and soft measurement, it is required to further improve the stability, accuracy and practicality of the online equipment, which is complementary to the long-time sampling offline detection method and rectified by offline detection.

5) For the intelligent incineration control equipment based on intelligent algorithms such as neural network, a large number of power plant operation data are required for its construction. In order to improve its control effect, acquired operation data are initially screened on the one hand to select the real and reasonable part as algorithm training data, other algorithms such as particle swarm algorithm and genetic algorithm can be introduced to further improve the algorithm generalization ability.

6) The prediction model for incineration temperature, acid gas temperature and dioxin concentration can provide references for the construction of an early warning system, so as to make an advance control, optimize the incineration effect and prevent excessive pollutants.

7) The previous and current researches mainly focus on intelligent control over subsystems, and the future research requires a systematic integration and takes emerging sensing, Internet of Things and artificial intelligence algorithm technology as supports to realize the data share by big-data analysis and cloud computing platform, construct an intelligent feedback and optimization model, develop intelligent incineration technologies and equipment, establish a fully-automatic unmanned intelligent incineration power generation system integrating source collection, transportation and classification, incineration power generation and residue purification, achieve the intelligent online dynamic optimization of equipment configured for waste power generation and its parameters and complete the whole process integration, platform management and diversification of technical solutions.

8) As the intelligentization involves multiple devices, multiple systems and interdisciplinary field, it is recommended that waste incineration companies communicate with each other and make progress together to realize the circulation of information and resources and provide supports for the establishment of relevant standards and regulations.