Cost calculation and prediction of producing green methanol by CO2 hydrogenation

CO2 capture, transportation, utilization and storage (CCUS) is an important technical path and technical guarantee to achieve the goal of carbon neutrality. The chemical and biological utilization technology of CO2 in China is basically in step with the international development level. In the preparation of high value-added chemicals, the technology of producing green methanol by hydrogenation of CO2 has attracted widespread attention and is relatively advanced. This technology is in the industrial demonstration stage at home and abroad, and the production cost is the key constraint condition for the industrialization of producing green methanol by hydrogenation of CO2.

Methanol is an important bulk basic chemical product, second only to ethylene, propylene and benzene. In recent years, the capacity and output of methanol in China have increased year by year, and the self-sufficiency rate is above 90% at present. According to the IHSMarkit report, in 2021, the capacity of methanol in China will reach 97.385 million tons, accounting for 67% of the global total capacity, and the total output will reach 78.1638 million tons, and the apparent consumption will account for 60% of the global total consumption. In China's methanol production capacity structure, coal-to-methanol accounts for about 80%, natural gas accounts for 8%, and coke oven gas accounts for 12%. The total carbon emission of methanol production is close to 200 million t/a, of which coal-to-methanol carbon emission accounts for 96.6% of the total emissions. ZHAO et al. pointed out in the report on the carbon footprint of methanol that the carbon emission of coal-to-methanol in the whole life cycle is 300gCO₂/MJ (equivalent to 5.85 tCO2/t methanol); In the report "Innovation Outlook: Renewable Methanol", the International Renewable Energy Agency (IRENA) defined the carbon cycle life path of green methanol. That is to say, the carbon emission footprint of green methanol in the whole life cycle from cradle to grave is 4~10gCO2/MJ (equivalent to 0.08~0.2tCO₂/t t methanol). According to this calculation, if green methanol is synthesized by using clean energy (biomass renewable CO2, photovoltaic wind power renewable electricity), the carbon emission of methanol industry will approach "0", which can not only reduce 96%~99% compared with coal-based methanol.

IRENA suggested that methanol should be divided into green, blue, gray and brown according to the source of raw materials, that is, when both H2 and CO2 sources are green or renewable energy, the methanol produced belongs to green methanol. Generally speaking, green methanol usually refers to methanol synthesized from green hydrogen (hydrogen production by green electrolysis of water) and renewable CO2 (such as from biomass reforming, air capture, etc.). As far as CO2 is concerned, in fact, it is of little significance to emphasize its source at present, because CO2 emission from industrial flue gas cannot be blocked in a short time, and capturing CO2 from flue gas and direct air has the same effect on carbon emission reduction. Therefore, in this paper, green methanol refers to methanol synthesized by H2 and CO2 (from biomass, air capture, flue gas capture, etc.) made from renewable energy.

In recent years, there has been a research upsurge at home and abroad on the production of green methanol from CO2 hydrogenation, and demonstration projects with the scale of 1,000 tons, 10,000 tons and 100,000 tons and above have been built one after another. The industry of producing green methanol from CO2 hydrogenation meets the strategic demand of "double carbon", but the production cost is the key factor whether the technology can develop rapidly and realize large-scale industrial application. In this paper, the production cost of producing green methanol from CO2hydrogenation is analyzed, calculated and predicted, and the process simulation is carried out by using AspenPlus software to comprehensively predict the production cost of green methanol synthesis, so as to provide reference for the development of this technology. The difference between CO2 hydrogenation to green methanol and coal-based methanol mainly lies in the different sources of feed gas (replacing CO2 with CO), and the others are similar. The process mainly consists of gas compression, synthesis reaction and rectification subsystems.

1 Cost trend forecast

In the feed gas, green hydrogen comes from green electricity to electrolyze water to produce hydrogen, and its cost is determined by the price of green electricity. According to "China Electric Power Industry Annual Development Report 2022", by the end of 2022, the installed capacity of power generation in China will reach about 2.6 billion kW, of which the total installed capacity of non-fossil energy will reach about 1.3 billion kW, and it is predicted that by 2025, the installed capacity of power supply in China will reach about 3 billion kW. According to the data reported by the Energy Research Institute of the National Development and Reform Commission, by the end of 2022, the installed capacity of wind power generation in China reached 29.6%, and the National Energy Administration predicted that the installed capacity of wind power generation would increase by 160 million kW in 2023, accounting for more than 32%. The national new energy electricity price policy requires that after 2022, the electricity price of scenery power generation will be connected to the Internet at a low price. According to reports, on June 22, 2021, the competitive configuration of the 200MW photovoltaic project in Zhengdou, the southern photovoltaic base of Ganzi Prefecture, Sichuan Province was calibrated, and the Sichuan Electric Power Company of the State Power Investment Group quoted a low price of 0.1476 yuan/(kW h), setting the lowest on-grid price for domestic photovoltaic projects. According to the report of the United Nations Global Compact Leaders Summit "Photovoltaic Industry Outlook 2025", it is predicted that by 2025, the global photovoltaic electricity price will drop to 1¢/(kWh) or even lower (about 0.067 yuan/(kWh)) on average. By 2025, the electricity cost of new photovoltaic projects in China will be lower than that of new coal-fired power projects by more than 30%. For CO2, the total CO2 emission in China will reach about 11 billion t/a in 2021, of which the power industry accounts for about 45% of the total emissions.

The International Energy Agency (IEA) predicts that the carbon capture of China power system will be about 170 million t in 2030, 800 million t in 2050 and 1.3 billion t in 2070, and the carbon capture of power system will account for 59.1% of the national total. The annual report of carbon dioxide capture, utilization and storage (CCUS) in China (2021) issued by the Ministry of Ecology and Environment shows that it is estimated that by 2025, the emission reduction of thermal power in China will reach 6 million t/a, and the peak value will be 200-500 million t/a in 2040. At present, the comprehensive cost of capturing 1tco exceeds that of 300 yuan (chemical absorption method), but with the continuous increase of capture scale and technical progress, such as the development of new efficient absorbent and process optimization, the capture cost will also decrease rapidly. Based on the above situation, generally speaking, there is a clear expectation that the price of green electricity will drop to 0.1 yuan/(kW h) and the price of CO2 will drop to 200 yuan/t in the next five years.

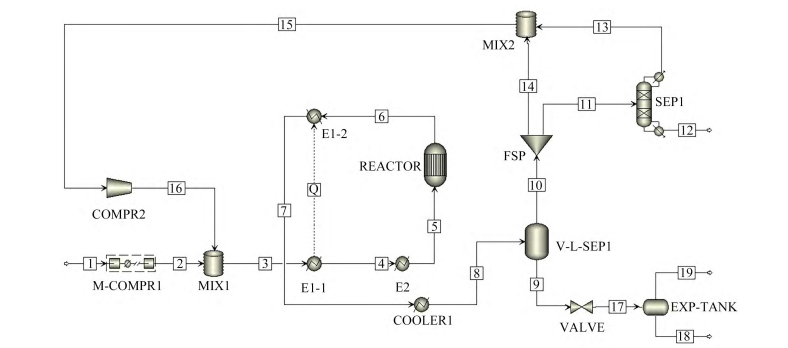

Fig.1 Schematic diagram of simulation process of carbon dioxide hydrogenation to methanol

The process cost includes utilities such as catalyst use, power consumption, circulating cooling water consumption and process gas consumption, among which catalyst is the main factor affecting the process cost. Studies have shown that the single-pass conversion rate of CO2 hydrogenation to methanol can reach up to 40% due to thermodynamic limitations. At present, there are Cu-based catalysts, metal oxides and precious metal catalysts which can be used for the hydrogenation of CO2 to methanol. The selectivity of methanol under different catalysts is obviously different, ranging from 40% to 99%. With the deepening of the research and application of the catalyst, it is expected that the overall performance of the catalyst will reach 40% one-way conversion and 99% methanol selectivity in the future. Based on this catalytic condition, this paper uses AspenPlus software to simulate the process, calculates the consumption of public works at this catalytic level to evaluate the process cost, and at the same time, considering the development factors such as catalyst technology maturity and market competition, it is predicted that the catalyst use cost will be reduced to 80 thousand yuan/t. The simulation process is shown in Figure 1.

The price of green electricity is the decisive factor of cost, which not only affects the production cost of green hydrogen, but also affects the process cost in public works, followed by the price of CO2. According to the data of methanol bulk futures trading, from the second half of 2022 to the first half of 2023, the spot price of methanol is around 2,450 ~ 2,700 yuan /t, and the total cost of coal-to-methanol is about 3,300 yuan/t. The cost and spot price are obviously upside down. The cost of raw coal and fuel coal for coal-to-methanol accounts for 70%~80% of the total production cost, and the impact of coal price trend on methanol cost is very obvious. With the increasing installed capacity of green electricity in China, the price of green electricity will continue to decrease. The above calculation shows that when the cost of green electricity is in 0.1 yuan/(kW h) (200 yuan /t of CO2 price), the production of green methanol will show great cost advantage. In addition, with the continuous improvement of carbon trading mechanism, carbon tax subsidies and other policies, when the production cost of CO2 hydrogenation to green methanol is solved, it will significantly promote the green transformation of methanol industry in China.

2 conclusion

1) The production cost of green hydrogen is the main factor affecting the production cost of green methanol from CO2 hydrogenation, and the price of green electricity determines the cost of hydrogen production. To reduce the production cost of green methanol, we must first solve the problem of green electricity price.

2) According to the calculation of the green methanol project with an annual output of 100,000 t, the production cost is close to 3,950 yuan /t, which is higher than that of the traditional coal-to-methanol system under certain catalytic synthesis conditions (30% conversion rate of CO2 and 80% methanol selectivity) and current main economic indicators (0.3 yuan/(kW h) green power and 320 yuan/tCO2).

3) It is predicted that the price of green electricity and CO2 will be reduced to 0.1 yuan/(kW h) and 200 yuan /t respectively in five years, and with the comprehensive progress of CCUS technology, the production cost of green methanol is expected to decrease by 59% compared with the current one, and it is significantly lower than that of coal-based methanol.

Source:https://mp.weixin.qq.com/s/5dybwteAbkjPWrw1MXGFrQ