U.S. Department of Energy (DOE) issued the Roadmap for Decarbonization Industry

Recently, the U.S. Department of Energy (DOE) released the Roadmap for Decarburization Industry, which identified four key ways to reduce industrial emissions from manufacturing industries in the United States and their R&D and demonstration needs. It put forward the key points and R&D and demonstration action plans for achieving net zero emissions by 2050 for five key carbon-intensive industries (steel, chemical, food, oil refining and cement), and put forward six action suggestions for R&D demonstration funding and government and industry actions. According to the roadmap, DOE issued a funding announcement of USD 1.05 billion on the same day to support the research and development of industrial emission reduction technologies, focusing on six areas: chemical decarbonization; Decarbonization of steel; And decarburization of food and beverage products; And decarbonization of cement and concrete; Decarbonization with paper-making forest products; Cross-domain decarbonization technology.

Data Source: “Annual Energy Outlook 2021 with Projections to 2050,” U.S. Energy Information Administration, Feb. 3, 2021.

The roadmap presents an agenda for government, industry, and other stakeholder to work together to accelerate emissions reductions and position the U.S. industrial sector as a global leader in innovation. The Roadmap for Industrial Decarbonization puts forward four key ways for industrial decarbonization in the United States:

(1) Improve energy efficiency. This approach provides the best opportunity for the implementation of short-term decarbonization solutions, which can immediately reduce emissions without major changes to industrial processes. The key objectives include: ① improving system efficiency, process output and heat energy recovery; ② Expand energy management; ③ Increase deployment of intelligent manufacturing to reduce energy consumption.

(2) Industrial electrification. More than 50% of manufacturing energy is used for heat treatment, and less than 5% of it is electrified. Industry electrification includes process thermal electrification or process hydrogen electrification, and the key objectives include: ① improving the energy efficiency of existing electrical technologies or hybrid systems; ② Innovative electrical system or hybrid system; ③ Overcome the economic and technical obstacles in implementing electrification technology in the existing process system based on fossil fuels.

(3) Low-carbon fuels, raw materials and energy substitution. This approach mainly includes flexible fuel technology, clean hydrogen fuel and raw materials, biofuel and raw materials, nuclear energy, concentrated solar thermal energy and geothermal energy.

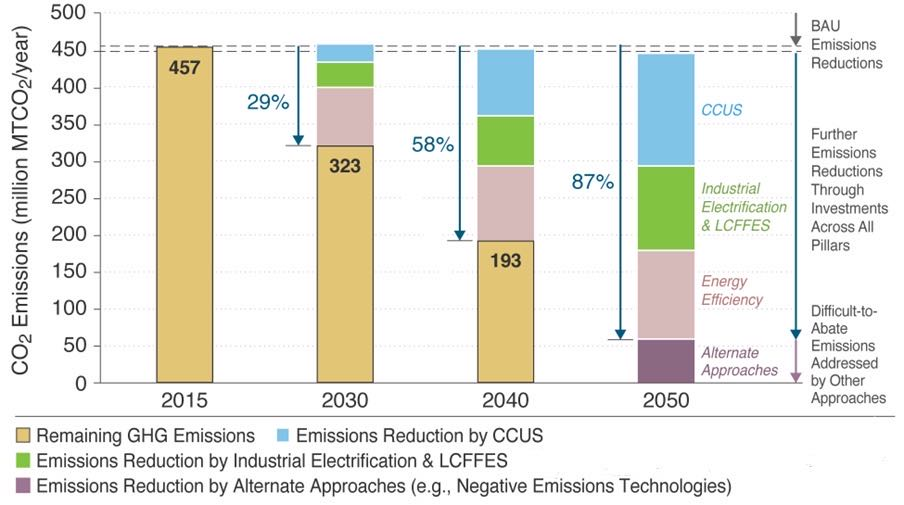

(4) Carbon Capture, Utilization and Storage (CCUS). The first three key approaches can be deployed before CCUS, and they can contribute about 40% of the target carbon emission reduction. CCUS can be the most powerful way to achieve long-term emission reduction, and its emphasis is on improving efficiency, economic feasibility and safety. The improvement of catalyst and process design is essential to improve efficiency, reduce cost and reduce material consumption or waste output.

Through the above key ways, the carbon emissions of five key industries can be reduced by 87% by 2050. To achieve zero net emissions, alternative methods and negative emission technologies are needed, which mainly include: ① land use ecosystem management activities, such as afforestation/reforestation, using biochar, and soil carbon management, etc. ② Bio-energy technology (BECCS) combined with CCS, CO2 capture from the air (direct air carbon capture), etc.

Data Source: “DOE Industrial Decarbonization Roadmap,” U.S. Department of Energy, September 2022.

Data Source: “DOE Industrial Decarbonization Roadmap,” U.S. Department of Energy, September 2022.

Source:

1. https://www.energy.gov/eere/doe-industrial-decarbonization-roadmap

2. Industrial Decarbonization Roadmap (energy.gov)

3. https://mp.weixin.qq.com/s/x6oVlaZa2GKYkisZ_U67DA