A New Attempt to Utilize Fly Ash from Domestic Waste Incineration: Fly Ash Modified Dry Desulfurization Technology

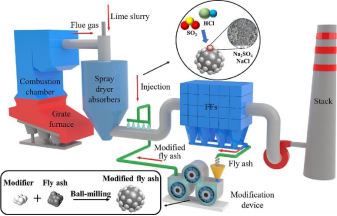

At present, the mainstream flue gas treatment process in waste incineration plants is SNCR, semi-dry deacidification, dry deacidification, activated carbon adsorption and bag dust removal, and the fly ash is semi-dry spraying tower bottom ash and powder collected by bag filter. The main components of fly ash include CaSO3, Ca(OH)2, CaCO3, CaClOH, NaCl, KCl, CaSO4, SiO2, etc. Fly ash contains high chlorine salt, which has low commercial value and is difficult to use. In developed countries in Europe and America, the main route of fly ash is to dispose of land (including landfill) after risk control.

From the perspective of material properties, fly ash has the characteristics of strong alkalinity and porous structure, and is a potential excellent desulfurization adsorbent. Its adsorption capacity is affected by many factors such as carbon content, pore structure, adsorption temperature, flue gas environment and so on.

Fly ash is modified by coupling mechanical force and alkaline substances, and the modified fly ash is mixed with flue gas again, so as to stimulate and improve the desulfurization reaction performance of fly ash materials, and the dust with excitation reaction and adsorption activity is sprayed into the flue again to adsorb acid gases such as SO2 and HCl and pollutants such as heavy metals, thus realizing the transformation of fly ash into adsorption materials. Fly ash is modified by physical ball milling to improve the adsorption capacity of acid gas, and then coupled with Ca(OH)2 or NaOH to realize the recycling and reduction of fly ash. Under the gas condition of simulating real flue gas, the removal rates of SO2 and HCl can reach 100% and 90% respectively. The characterization analysis of fly ash particles shows that mechanochemical method has a good crushing effect on fly ash, which can improve the ability of fly ash to remove SO2 and HCl from waste incineration flue gas. Mechanical modification of fly ash can be used as a platform technology for fly ash reuse and development.

Based on the mainstream desulfurization process of semi-dry flue gas from waste incineration, the technical route of "fly ash collection-on-line modification-dry re-adsorption" is put forward for the first time with the idea of reducing the source and improving the efficiency of the process.

Source:https://www.sciencedirect.com/science/article/abs/pii/S0016236123009675