Design of collaborative drying system for sludge incineration

This issue introduces a novel dual circulating fluidized bed technology for thermal treatment of socialist sewage sludge with recovery of nutr published in Waste Management. Ients and energy, this paper puts forward a sludge incineration technology and incineration disposal scheme, and discusses some "disputes" about sludge incineration path, including energy balance, tail gas pollution, ash resource recovery potential, etc.

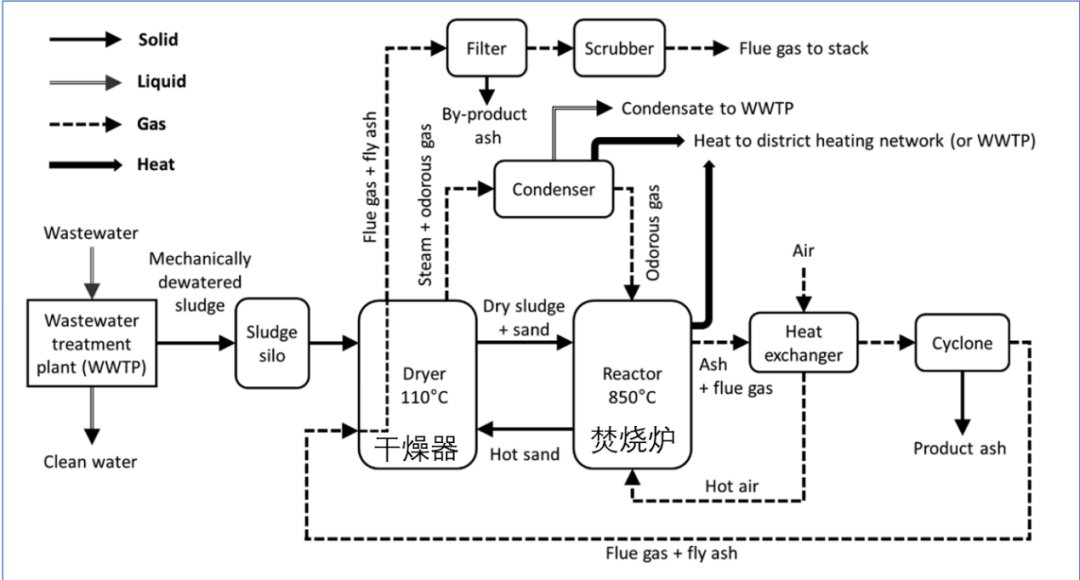

Fig. 1 is the flow chart of the sludge incineration disposal scheme, which mainly includes two units in structure, namely, fluidized bed drying unit and fluidized bed incineration unit, which is also one of the highlights of the scheme-the drying unit and incineration unit are designed and operated as a whole. Sludge with water content of 80% first enters the drying unit and is mixed with hot sand returned from the incineration unit (staying for 100~300 s) to reduce the water content, and the proportion of dry matter can be increased to 98 wt% before entering the incinerator. Then, the mixture of dried sludge and sand is sent to the fluidized bed incinerator unit, and the incineration reduction can be realized at 850℃ for 1000 s, and the ash volume accounts for 8% of the feed sludge volume. The whole process of this scheme is operated in a low-pressure environment, which can effectively prevent the malodorous gas from escaping and leaking.

Fig. 1 process schematic diagram

From the demonstration of the sludge incineration scheme (the treatment capacity of rovaniemi sludge incineration plant is 10000 t/a), the scheme has the following advantages:

1) Self-sufficiency in energy, the process needs the assistance of external energy input in the start-up stage, and completely realizes energy balance in the normal continuous operation stage without additional energy input. In this process scheme, the drying unit and the incineration unit are designed as a whole and coordinated for operation and maintenance, thus achieving the overall energy balance of "drying-incineration".

2) To reduce the pollution risk of heavy metals in ash resource recovery, the overall design scheme of "drying-incineration" introduced in this paper has also been optimized in ash recovery and treatment. The ash from the incineration unit is carried with the flue gas into the ash recovery/flue gas disposal unit, which consists of two modules: high-temperature cyclone separator and bag filter. The two modules use temperature to selectively recover ash, which has avoided the influence of heavy metals.

3) When the tail gas emission reaches the standard, various air pollutants will be released during the combustion process, among which NOX, CO, SOX(SO2), HCl, HF, total organic carbon (TOC), particulate matter (dust), polychlorinated dioxins and furans (dioxins) and heavy metals are the main environmental pollutants. The incineration demonstration plant mentioned in the article has been put into trial operation for 7 days, and the exhaust gas has reached the standard.

Therefore, based on the above three aspects, the scheme proves that domestic concerns about sludge incineration as a high-energy-consuming process, atmospheric pollutants generated by tail gas emission and heavy metals in recycled sludge ash are redundant, and the scheme provides some ideas and references for the development of sludge incineration process in China.Design of collaborative drying system for sludge incineration.

Source:

[1] Proll T , Kolbitsch P, Bolhar-Nordenkampf J. A Novel Dual Circulating Fluidized Bed System for Chemical Looping Processes.

[2] The development plan of urban sewage treatment and resource utilization in the Tenth Five-Year Plan

[3] Hao Xiaodi, Chen Qi, Li Ji, Jiang Han. There is no need to worry about tail gas pollutants in sludge incineration [J]. China Water & Wastewater.

[4] https://mp.weixin.qq.com/s/p_ez_yrtiI6XqodJdktaQA