Zhejiang Shuren University’s Pan Hua, Zhejiang University of Technology’s Jun Chen, and Xi’an Jiaotong University’s Chi He: Core–Shell MnOx@CeSnOx with Electronic Interactions Improves Sulfur Toleranc

NOx and chlorinated VOCs (CVOCs) often co-exist in municipal solid waste incineration (MSWI) flue gas, yet simultaneous catalytic removal is difficult because high activity and sulfur resistance typically trade off. This work reports a core–shell MnOx@CeSnOx catalyst that maintains strong performance under SO2 exposure during the combined removal of NOx and chlorobenzene (CB).

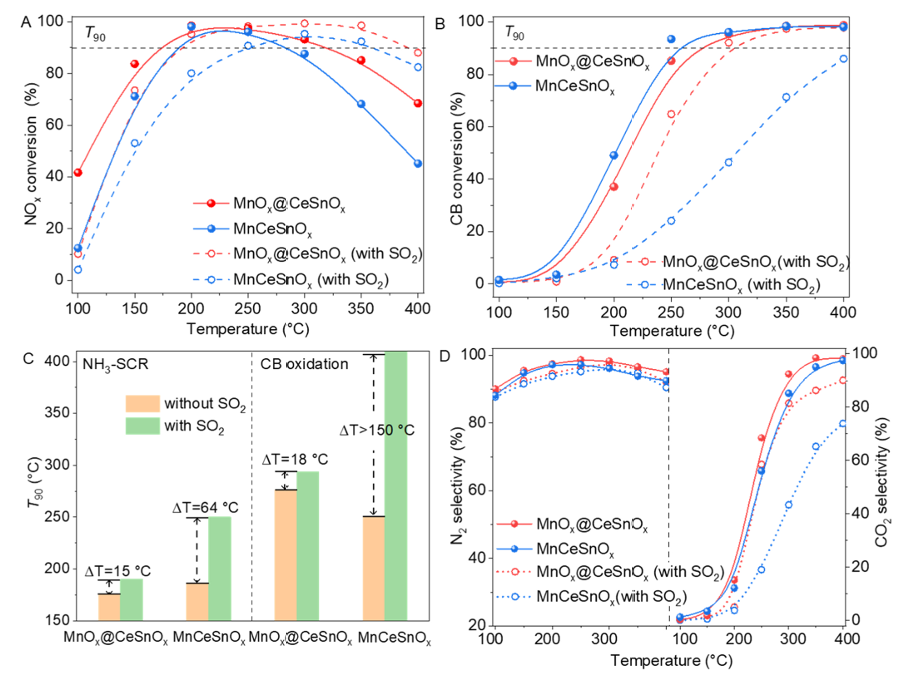

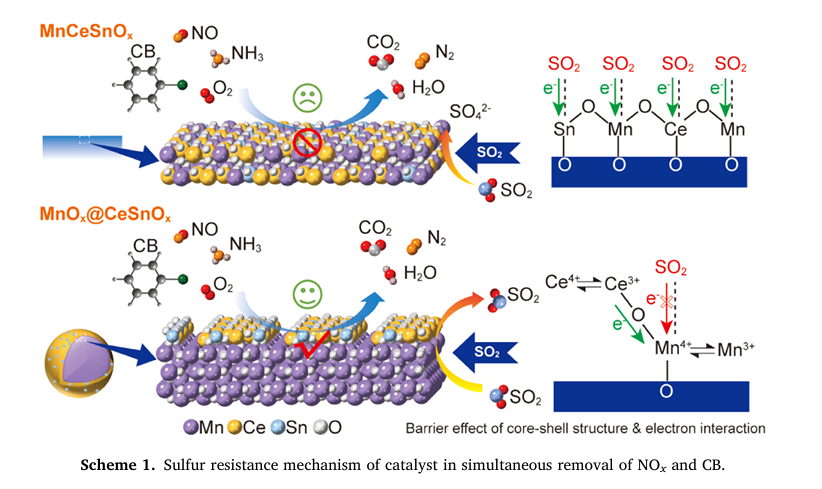

In the presence of 50 ppm SO2, MnOx@CeSnOx sustained >90% conversion of both NOx and CB across a wide temperature window (294–392°C). Compared with SO2-free conditions, the T90 shift (temperature for 90% conversion) was limited to only 15–18°C. In contrast, the reference MnCeSnOx catalyst suffered severe SO2 poisoning, with T90 increasing by 64°C for NOx and by more than 150°C for CB, eliminating the operating window for achieving 90% conversion of both pollutants.The enhanced sulfur tolerance is attributed to a three-fold “physical barrier–sacrificial adsorption–electronic regulation” mechanism enabled by the CeSnOx shell. First, the compact shell physically shields Mn active sites from direct SO2 attack. Second, SnOx in the shell acts as a preferential sacrificial site, consuming SO2 via sulfate formation and protecting Mn-centered sites. Third, Ce–O–Mn interfacial bonding promotes electron transfer from Ce3+ to adjacent Mn4+, weakening SO2–Mn4+ interactions and suppressing Mn sulfate formation. Together, these effects mitigate irreversible sulfur poisoning while preserving the redox and acidic features needed for NH3-SCR and CB oxidation.

This study targets catalytic multi-pollutant control for MSWI flue gas, focusing on simultaneous NOx reduction and chlorinated VOC oxidation under sulfur-containing conditions. The reported core–shell strategy provides guidance for designing sulfur-resistant catalysts for practical incineration applications.